Forklift Signs-- Increase Safety Awareness in High-Traffic Areas

Forklift Signs-- Increase Safety Awareness in High-Traffic Areas

Blog Article

Key Considerations for Creating Effective Forklift Safety Indications

When developing effective forklift safety and security indications, it is important to consider several basic aspects that collectively guarantee optimal presence and quality. High-contrast shades coupled with huge, understandable sans-serif font styles considerably boost readability, particularly in high-traffic areas where fast understanding is vital. forklift signs. Strategic placement at eye level and the usage of sturdy materials like light weight aluminum or polycarbonate further contribute to the long life and efficiency of these indicators. Furthermore, adherence to OSHA and ANSI guidelines not just standardizes safety and security messages yet additionally bolsters conformity. To completely realize the complexities and finest techniques entailed, several additional considerations advantage closer interest.

Color and Comparison

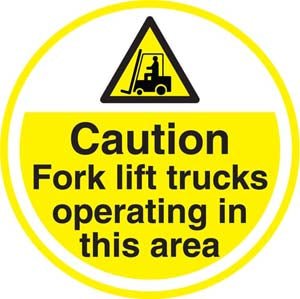

While designing forklift safety indicators, the selection of shade and contrast is paramount to making certain presence and performance. The Occupational Security and Health And Wellness Administration (OSHA) and the American National Requirement Institute (ANSI) offer guidelines for using shades in security indicators to standardize their significances.

Efficient contrast in between the history and the text or symbols on the indication is just as important. High comparison ensures that the indication is legible from a range and in varying illumination problems. As an example, black message on a yellow background or white text on a red history are mixes that stand out prominently. Furthermore, making use of reflective materials can boost presence in low-light settings, which is often a consideration in storage facility settings where forklifts run.

Making use of suitable shade and contrast not only sticks to governing requirements yet likewise plays an essential role in maintaining a risk-free workplace by ensuring clear interaction of hazards and instructions.

Typeface Dimension and Design

When developing forklift safety signs, the option of typeface size and style is critical for guaranteeing that the messages are clear and swiftly recognized. The key purpose is to enhance readability, specifically in atmospheres where fast info handling is important. The font style size need to be big enough to be reviewed from a distance, suiting varying view problems and guaranteeing that workers can comprehend the indication without unnecessary pressure.

A sans-serif font is usually suggested for safety indications due to its tidy and straightforward look, which enhances readability. Typefaces such as Arial, Helvetica, or Verdana are typically chosen as they lack the detailed information that can obscure vital information. Uniformity in font style throughout all safety and security indications help in creating an uniform and specialist look, which even more reinforces the importance of the messages being shared.

Furthermore, focus can be achieved with tactical use of bolding and capitalization. By carefully picking proper font style sizes and styles, forklift safety signs can efficiently interact critical safety and security info to all personnel.

Positioning and Exposure

Guaranteeing ideal positioning and presence of forklift safety indications is vital in industrial settings. Correct indicator positioning can dramatically reduce the threat of mishaps and boost general work environment safety.

Lighting conditions additionally play an essential role in visibility. Signs ought to be well-lit or made from reflective products in dimly lit areas to guarantee they are noticeable in all times. The usage of contrasting shades can even more boost readability, especially in atmospheres with differing light conditions. By thoroughly taking into consideration these elements, one can guarantee that forklift safety signs this are both reliable and noticeable, consequently promoting a much safer working setting.

Material and Toughness

Picking the appropriate products for forklift safety and security signs is vital to guaranteeing their long life and effectiveness in industrial environments. Offered the rough problems often encountered in storage facilities and producing facilities, the materials selected have to withstand a variety of stressors, including temperature level changes, dampness, chemical direct exposure, and physical effects. Long lasting substratums such as aluminum, high-density polyethylene (HDPE), and polycarbonate are prominent choices as a result of their resistance to these aspects.

Light weight aluminum is renowned for its robustness and corrosion resistance, making it an outstanding choice for both indoor and outside applications. HDPE, on the various other hand, provides outstanding influence resistance and can sustain prolonged exposure to severe chemicals without breaking down. Polycarbonate, understood for its high effect strength and clarity, is often utilized where presence and resilience are paramount.

Equally vital is the type of printing made use of on the signs. UV-resistant inks and safety coverings can substantially improve the life expectancy of the signs by stopping fading and wear brought on by extended direct exposure to sunshine and various other ecological aspects. Laminated or screen-printed surfaces supply added layers of protection, making certain that the crucial safety details remains clear in time.

Purchasing high-grade materials and durable manufacturing refines not just extends the life of forklift security indicators but likewise click this strengthens a society of safety within the workplace.

Compliance With Regulations

Sticking to regulatory requirements is extremely important in the design and release of forklift safety and security indications. Conformity makes certain that the signs are not only effective in communicating important safety and security details yet also meet legal responsibilities, therefore reducing prospective obligations. Different companies, such as the Occupational Security and Wellness Management (OSHA) in the USA, supply clear standards on the requirements of safety and security indications, including color design, message size, and the addition of widely acknowledged symbols.

To comply with these policies, it is necessary to carry out an extensive evaluation of applicable requirements. For example, OSHA mandates that safety signs should show up from a distance and include certain shades: red for danger, yellow for care, and environment-friendly for safety directions. In addition, adhering to the American National Criteria Institute (ANSI) Z535 collection can additionally enhance the effectiveness of the indicators by standardizing the layout aspects.

Furthermore, normal audits and updates of safety and security indications should be performed to guarantee continuous compliance with any kind of changes in laws. Engaging with licensed security professionals throughout the style phase can also be valuable in guaranteeing that all regulatory demands are satisfied, which the indications offer their desired objective properly.

Final Thought

Creating effective forklift safety and security indicators needs mindful interest to shade contrast, font dimension, and design to guarantee optimum visibility and readability. Strategic placement at eye degree in high-traffic areas improves recognition, while the use of resilient materials ensures durability in numerous environmental conditions. Adherence to OSHA and ANSI standards standardizes safety messages, and including reflective products enhances visibility in low-light scenarios. These considerations collectively contribute to a more secure working setting.

Report this page